I originally met the Sasakis in response to a leaking issue into their fireplace. When I arrived to investigate I was shown to built-in (or bricked in) wood-burning fireplace insert. This particular type of unit was very unique. The cast-iron stove used a clay (or masonry) flue liner instead of a metal flue liner, like most other units. The clay tiles were constructed directly on top of the unit. Furthermore, the facing brick (or interior) brick was also constructed on top of the stove in an arch pattern. This type of unit was most commonly installed in the 80’s, and can only be installed in a newly constructed chimney.

I originally met the Sasakis in response to a leaking issue into their fireplace. When I arrived to investigate I was shown to built-in (or bricked in) wood-burning fireplace insert. This particular type of unit was very unique. The cast-iron stove used a clay (or masonry) flue liner instead of a metal flue liner, like most other units. The clay tiles were constructed directly on top of the unit. Furthermore, the facing brick (or interior) brick was also constructed on top of the stove in an arch pattern. This type of unit was most commonly installed in the 80’s, and can only be installed in a newly constructed chimney.

After inspecting where the leaking issue may be coming from I found that the unit was badly damaged. After years of a slow leak through the chimney cap, the stove has suffered serious water damage and was rusting through. The unit was old, damaged, inefficient and unsafe. It had to be replaced. Hmm how do we remove the stove with not only the entire facing built on top of it but 30 ft of heavy clay flue tile liners.

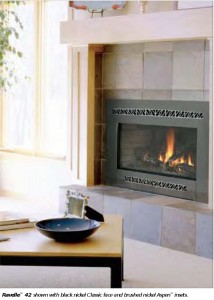

After the gentle delivery of some very bad news, my investigation deepened to see what options we have to fix this problem. After punching an inspection hole in the rear of the chimney, I was able to determine that if I removed the facing, I may have a shot at removing the interior cinder block and flue tile that was pinning the stove to the ground. I wrote up an action plan and we started exploring replacement fireplace options. The Sasaki’s decided to go with a Lennox Ravelle Zero Clearance Gas Fireplace.

Since we had to remove the mantle and brick facing anyways, the Sasaki’s decided they would like to replace them with something a bit more modern. During our search for a proper replacement fireplace insert, Mrs Sasaki saw a picture of a fireplace, mantle, and facing style that she really liked. After a bit more discussion, it turns out it was exactly what she wanted, except for the fireplace trim. I was excited to take on the challenge.

I began a week before the job building the mantle in my garage. I found some really straight and nice pieces of pine wood and began cutting and gluing the mantle and surround. As you can notice, the tiling wraps the corner into the surround pieces, making construction and installation a bit tricky.

Day 1 of the job went incredibly smooth. The brick facing came down quickly and easily and I had no problems removing the old rusted insert. The fireplace has already been wired with 110 electric so just crossing a few wires made that easy. We plumbed a new gas line and installed the fireplace insert.

Now the reno vation began. The facing was going to be changed completely and the mantle covered. We are doing a tile facing and hearth, and we are finishing with sheet rock above where the mantle will be. After the 2×4 construction was complete I covered the lower portion in concrete board and sheet rocked the top.

vation began. The facing was going to be changed completely and the mantle covered. We are doing a tile facing and hearth, and we are finishing with sheet rock above where the mantle will be. After the 2×4 construction was complete I covered the lower portion in concrete board and sheet rocked the top.

I covered the hearth in tile first and installed the mantle mounting bracket on top. After finshing tiling the facing I was able to quickly snap the surround pieces in place and throw on the mantle. Finally finished with a bit of grout, sheet rock mud, sanding, and paint.

After finishing on time, exactly as I had planned, the Sasaki’s were thrilled. Not only did they love their new fireplace, but they seemed to enjoy the experience and offered a very generous tip. It’s not everyday you meet clients that are able to express their appreciation for my hard work as the Sasaki’s. Thank you for the wonderful experience. You are a preferred customer for life.

Happy Burning,

Pristine Sweeps

By: Aaron Woodward